An engine mounting system serves two basic functions: supporting the engine and isolating its vibration. The exciting force generated during engine operation consists of two parts: The first part results from the pulse pressure in the cylinders due to non-uniform engine ignition and engine operation in unbalanced status. The second part is vibration excitation caused by bumpy road.

The vibration of certain order at natural frequency may be significant in amplitude and generate large noise. The power assembly mounting system serves as the connection between the engine and the vehicle body, providing the main function of attenuating large low-frequency vibration of the engine and suppressing high-frequency noise in the driver’s cab.

Design of an engine mounting system should consider the following technical requirements:

The mounting system should provide high static stiffness to support the power assembly and maintain stable output torque. High damping should be achieved for attenuating large low-frequency vibration of the engine rapidly.

In order to reduce vibration transmission rate from the power assembly to the driver’s cab, and to effectively suppress high-frequency noise in the driver’s cab, the mounting system should provide low damping and low dynamic stiffness at high frequencies.

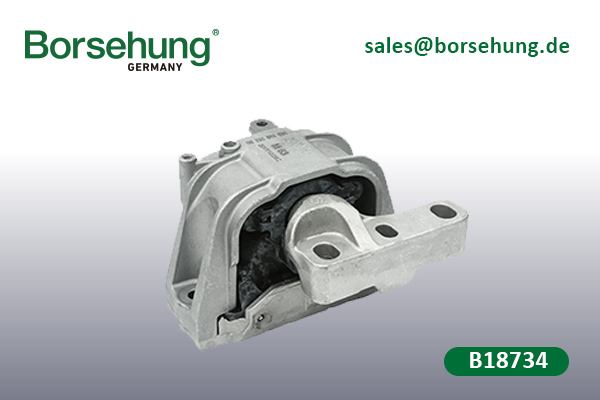

Name: engine mounting

Ref No.: 1K0199262M

Applicable models of engine mounting:

Skoda: OCT 04-13/SUP 08-15/YET 10-14

VW: BE 17-/BEC 17-/CA 04-15/CC 12-17/EOS 06-16/GOC 12-16/GOLF 04-14/GOPL 05-09/JE 06-15/PA 06-16/PACC 09-12/SCI 09-18/TOU 03-10

SEAT: ALT 04-15/LE 06-13/TO 05-09

Audi: A3 04-13/A3CA 08-13/ATT 07-10